We Offer Services

PAWAN INDUSTRIES offers a wide range of products and services to the airline industry. We repair and supply our customers with the finest in upholstery, carpet, leather and seat cushions and minor repair of thermoformed cabin interiors including Tray table, Arm Cap, Arm rest, toilet seats, shrouds and similar components to enhance the comfort of their aircraft. Additionally, we provide finished products such as seat covers, carpet, curtains and Seat covers that are ready to install. All meet FAA standards for flammability.

At the core of Pawan Industries for Aircraft Interior Services, we ensured customer satisfaction by reducing the cost, on time delivery with highest quality.

Our Facility offers various types of services including;

- Fabrication /Repair of Seat Cover

- Fabrication/Repair of Carpets floor covering/edge binding/tape binding etc.

- Dry Cleaning of Fabric/Leather Seat Covers

- Repair of Plastic Parts

- Repair of Thermoformed Plastic Panels

- Repair of Cargo Net Door

- Fabrication / Repair of Curtains

- Cleaning the Screen Assy/ Lap Belt Assy

- Painting Polishing of Side Door Trims, Panels

- Aircraft trestle

- Aircraft paint touch up

- Wooden and metal part veneer coating

- Aircraft livery, decal and sticker

- Aircraft Blanking and Covers

- Aircraft Interior and Exterior cleaning

- Supply of aircraft consumables and spare parts

Refurbishment of Aircraft

The importance of refurbishing your aircraft cannot be overstated. In the dynamic world of aviation, where every detail contributes to overall performance and passenger satisfaction, ensuring your aircraft's interior is up to par is essential.

At Pawan Industries (PI), we understand the significance of aircraft refurbishment and upgrades. With our expertise in this field, we can help you navigate the complexities involved in transforming your aircraft's interior to meet modern standards and expectations.

Refurbishing your aircraft offers numerous benefits:

1. Enhanced Comfort: A refurbished interior provides a more comfortable and enjoyable experience for passengers, contributing to overall satisfaction during flights.

2. Modernization: Keeping up with the latest trends and technologies in aircraft interiors ensures your aircraft remains competitive and appealing in the market.

3. Increased Value: A well-maintained and modernized interior enhances the overall value of your aircraft, making it more attractive to potential buyers or lessees.

4. Safety and Compliance: Refurbishing allows for the integration of updated safety features and ensures compliance with current regulations and standards.

5. Customization: Refurbishment offers the opportunity to personalize the interior according to your preferences, branding, and specific needs.

6. Efficiency: Upgrading outdated systems and components can improve operational efficiency and reduce maintenance costs in the long run.

Whether you're considering a minor refresh or a complete interior overhaul, refurbishing your aircraft is a strategic investment that yields significant returns. With our team of experts at Pawan Industries (PI), you can rest assured that your aircraft refurbishment project will be handled with precision, professionalism, and a commitment to excellence.

Contact us today to learn more about how we can help elevate your aircraft's interior to new heights.

Aircraft Cabin Repair

Repairing polycarbonate and leather components in an aircraft cabin is a critical aspect of maintaining the interior's aesthetics, functionality, and safety. Here's a breakdown of the process involved:

1. Assessment: Begin by thoroughly inspecting the polycarbonate and leather components to identify any damage, such as scratches, cracks, tears, or discoloration. Assess the extent of the damage and determine whether repair or replacement is necessary.

2. Cleaning: Clean the damaged areas using appropriate cleaning solutions and methods suitable for polycarbonate and leather materials. Ensure that the surfaces are free from dirt, debris, and oils before proceeding with repairs.

3. Polycarbonate Repair:

- For minor scratches or scuffs on polycarbonate surfaces, use a fine-grit sandpaper to gently sand the affected area in a circular motion until the scratches are no longer visible.

- For deeper scratches or cracks, apply a polycarbonate repair kit or filler compound to fill in the damaged areas. Follow the manufacturer's instructions for application and curing.

4. Leather Repair:

- For minor scratches or surface damage on leather upholstery, use a leather repair kit to fill in the damaged areas with a matching color compound. Smooth out the compound and allow it to dry according to the manufacturer's instructions.

- For more significant damage such as tears or large areas of wear, consider patching or replacing the affected leather panels. This may require professional assistance to ensure a seamless repair.

5. Polishing and Finishing:

- Once the repairs are complete, polish the polycarbonate surfaces using a specialized polishing compound to restore shine and clarity.

- For leather upholstery, apply a leather conditioner or protector to nourish and protect the repaired areas, enhancing their appearance and longevity.

6. Quality Assurance:

- After completing the repairs, conduct a final inspection to ensure that the polycarbonate and leather components are restored to their original condition. Verify that all repairs meet safety and regulatory standards for aircraft interiors.

7. Documentation:

- Document the repair process, including before and after photos, materials used, and any relevant maintenance records. This documentation can be valuable for future reference and regulatory compliance.

By following these steps and employing appropriate techniques and materials, you can effectively repair polycarbonate and leather components in an aircraft cabin, ensuring a safe, comfortable, and visually appealing interior for passengers and crew alike.

Aircraft Cabin Maintenance

Cabin maintenance of an aircraft is a critical aspect of ensuring passenger safety, comfort, and overall flight experience. Here are some key elements involved in cabin maintenance:

1. Cleaning and Sanitization: Regular cleaning and sanitization of the cabin surfaces, including seats, tray tables, armrests, and lavatories, are essential to prevent the spread of germs and ensure a hygienic environment for passengers and crew.

2. Interior Inspection: Routine inspections of the cabin interior are conducted to identify any signs of wear and tear, damage, or malfunctioning components. This includes checking for loose fittings, damaged upholstery, broken or malfunctioning entertainment systems, and malfunctioning lighting.

3. Seat Maintenance: Seats undergo regular maintenance to ensure they are in optimal condition. This may involve repairing damaged upholstery, replacing worn-out cushions, tightening loose fittings, and lubricating moving parts such as recline mechanisms and armrests.

4. Cabin Furnishings: The furnishings in the cabin, including carpets, curtains, and wall panels, are inspected and maintained to ensure they are clean, intact, and free from damage. Any damaged or worn-out furnishings are repaired or replaced as needed.

5. Galley and Lavatory Maintenance: The galley and lavatory areas are thoroughly cleaned and sanitized after each flight. Additionally, routine maintenance is performed to ensure all fixtures, plumbing, and equipment are in proper working order.

6. Emergency Equipment: Emergency equipment, such as oxygen masks, life vests, and emergency exits, are inspected and maintained to ensure they are operational and compliant with safety regulations.

7. Compliance with Regulations: Cabin maintenance procedures adhere to strict regulatory requirements set forth by aviation authorities such as the Directorate General of Civil Aviation (DGCA), Federal Aviation Administration (FAA) and the European Aviation Safety Agency (EASA). Compliance with these regulations is essential to ensure the safety and airworthiness of the aircraft.

Overall, cabin maintenance plays a crucial role in maintaining the safety, comfort, and overall satisfaction of passengers during flight. By implementing comprehensive maintenance procedures and adhering to regulatory requirements, airlines can ensure that their aircraft cabins are well-maintained and provide a positive travel experience for passengers.

Aircraft Seat Covers

Pawan Industries is a leading manufacturer and provider of aircraft seat covers and maintenance services. Our company specializes in producing high-quality seat covers for various types of aircraft, including commercial airliners, private jets, helicopters, and more.

Our seat covers are crafted using durable materials that meet stringent aviation standards for safety and reliability. We offer a wide range of designs and customization options to suit the unique preferences and requirements of our clients.

In addition to manufacturing seat covers, Pawan Industries also provides comprehensive maintenance services for aircraft interiors. Our team of skilled technicians is trained to perform thorough inspections, repairs, and upgrades to ensure that your aircraft's seats are in optimal condition.

At Pawan Industries, we are committed to delivering exceptional products and services that meet the highest industry standards. Contact us today to learn more about our aircraft seat covers and maintenance solutions.

Manufacturing and maintaining aircraft seat covers require adherence to strict regulations and quality standards due to the critical nature of aviation safety. Here's a general overview of the process:

Manufacturing Aircraft Seat Covers:

1. Design Phase: Collaborate with aircraft manufacturers or airlines to understand specific requirements such as seat dimensions, materials, safety standards, and branding elements.

2. Material Selection: Choose high-quality, durable, flame-retardant materials that meet aviation safety regulations. Common materials include leather, fabric, and synthetic materials.

3. Cutting & Sewing: Use computer-aided design (CAD) software and cutting machines to ensure precision cutting of materials. Skilled technicians then sew the pieces together following the design specifications.

4. Testing: Conduct various tests to ensure compliance with safety standards, including flame resistance, abrasion resistance, colorfastness, and durability tests.

5. Quality Control: Implement strict quality control measures at every stage of production to identify and rectify any defects or deviations from specifications.

6. Certification: Obtain necessary certifications from aviation authorities such as the Federal Aviation Administration (FAA) or European Aviation Safety Agency (EASA) to ensure airworthiness.

Maintenance of Aircraft Seat Covers:

1. Routine Inspection: Regularly inspect seat covers for signs of wear and tear, damage, or degradation.

2. Cleaning and Sanitization: Follow prescribed cleaning procedures to maintain cleanliness and hygiene standards. Use approved cleaning agents that do not compromise the integrity of the materials.

3. Repair and Replacement: Repair or replace damaged seat covers promptly to prevent further deterioration and ensure passenger comfort and safety.

4. Documentation: Maintain detailed records of maintenance activities, including inspections, repairs, and replacements, to comply with regulatory requirements and track the service life of seat covers.

5. Compliance Checks: Periodically review seat covers to ensure continued compliance with aviation safety regulations and standards.

Regulations and Standards:

- Directorate General of Civil Aviation (DGCA): The DGCA oversees civil aviation in India and sets regulations and standards for aircraft maintenance and operations.

- Federal Aviation Administration (FAA): The FAA sets regulations and standards for aircraft seat covers in the United States.

- European Aviation Safety Agency (EASA): EASA establishes similar regulations and standards for aircraft seat covers in Europe.

- International Air Transport Association (IATA): IATA may also provide guidelines and recommendations related to aircraft interior maintenance, including seat covers.

Manufacturers and maintenance providers in this industry must stay abreast of regulatory changes and technological advancements to deliver safe, high-quality products and services to the aviation industry.

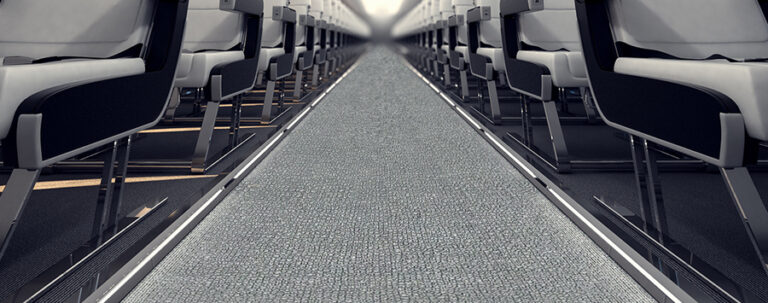

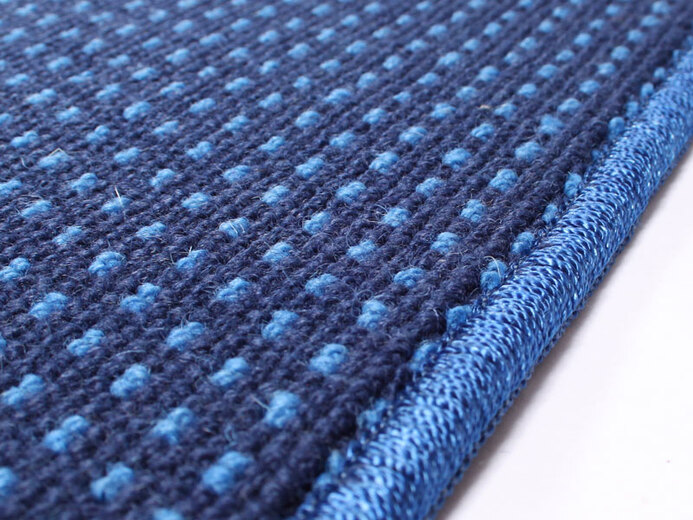

Aircraft Carpet

The luxurious interior of the aircraft boasts a floor adorned with a plush and sumptuous carpet, adding an element of comfort and elegance to the cabin ambiance. The carpet's rich texture and softness not only provide a welcoming atmosphere but also contribute to the overall aesthetic appeal of the aircraft's interior design. Whether passengers are embarking on a short journey or a long-haul flight, the indulgent carpeting enhances their travel experience, making them feel pampered and relaxed throughout their time in the air.

The quality of aircraft carpeting is of paramount importance in ensuring passenger comfort, safety, and overall satisfaction. Here are some key factors that contribute to the quality of aircraft carpet:

1. Durability: Aircraft carpet must be highly durable to withstand heavy foot traffic, rolling luggage, and frequent cleaning. High-quality carpeting is made from durable materials that resist wear and tear, maintaining their appearance and integrity over time.

2. Fire Resistance: Safety is a top priority in aviation, so aircraft carpeting must meet strict fire safety standards. High-quality aircraft carpet is typically treated with fire-retardant chemicals or manufactured using inherently flame-resistant materials to minimize the risk of fire and smoke propagation.

3. Stain Resistance: Spills and stains are inevitable in the confined space of an aircraft cabin. Quality aircraft carpeting is treated with stain-resistant coatings or features inherent stain resistance, making it easier to clean and maintain.

4. Anti-Slip Properties: To prevent slips and falls, especially during turbulence, aircraft carpeting should have anti-slip properties. The carpet's surface texture and backing design contribute to its ability to provide traction and stability underfoot.

5. Sound Absorption: Aircraft cabins can be noisy environments due to engine noise, air circulation, and passenger chatter. High-quality carpeting with sound-absorbing properties helps to reduce noise levels, creating a quieter and more comfortable cabin environment.

6. Comfort: Comfort is a key consideration for passenger satisfaction during air travel. Quality aircraft carpeting provides a soft and comfortable surface underfoot, enhancing the overall passenger experience during long flights.

7. Aesthetic Appeal: While functionality is essential, the appearance of aircraft carpeting also contributes to the overall ambiance of the cabin. High-quality carpeting comes in a range of colors, patterns, and textures to complement the aircraft's interior design and create a welcoming atmosphere for passengers.

8. Easy Maintenance: Efficient cleaning and maintenance are essential for keeping aircraft cabins clean and hygienic. Quality carpeting should be easy to vacuum, spot clean, and maintain, minimizing downtime between flights and ensuring a fresh and inviting cabin environment.

Airlines and aircraft manufacturers invest in high-quality carpeting that meets regulatory requirements, enhances passenger comfort and safety, and withstands the rigors of commercial aviation operations. Regular inspection, cleaning, and replacement schedules are implemented to maintain the quality and integrity of aircraft carpeting throughout its service life.

Aircraft Flooring

Aircraft non-textile flooring refers to flooring materials used in aircraft cabins that are not made of traditional textiles such as carpet. These materials are chosen for their durability, ease of maintenance, and resistance to wear and tear. Some common types of non-textile flooring used in aircraft cabins include:

1. Vinyl Flooring: Vinyl flooring is a popular choice for aircraft cabins due to its durability, ease of cleaning, and resistance to moisture. It comes in various styles and designs, including wood, stone, and tile patterns, allowing for customization to match the interior décor of the aircraft.

2. Rubber Flooring: Rubber flooring is resilient and offers excellent traction, making it ideal for high-traffic areas in aircraft cabins such as entrances and galley areas. It is also easy to clean and maintain, making it a practical choice for airlines.

3. Linoleum Flooring: Linoleum is a natural flooring material made from linseed oil, wood flour, cork dust, and resin. It is durable, eco-friendly, and available in a wide range of colors and patterns, making it suitable for aircraft cabin flooring.

4. Laminate Flooring: Laminate flooring consists of layers of synthetic materials fused together under high pressure. It is scratch-resistant, easy to clean, and available in various designs that mimic the look of wood, stone, or tile.

5. Epoxy Flooring: Epoxy flooring is a seamless, durable, and chemical-resistant flooring option suitable for aircraft cabins. It is often used in areas where spills are common, such as lavatories and galley kitchens.

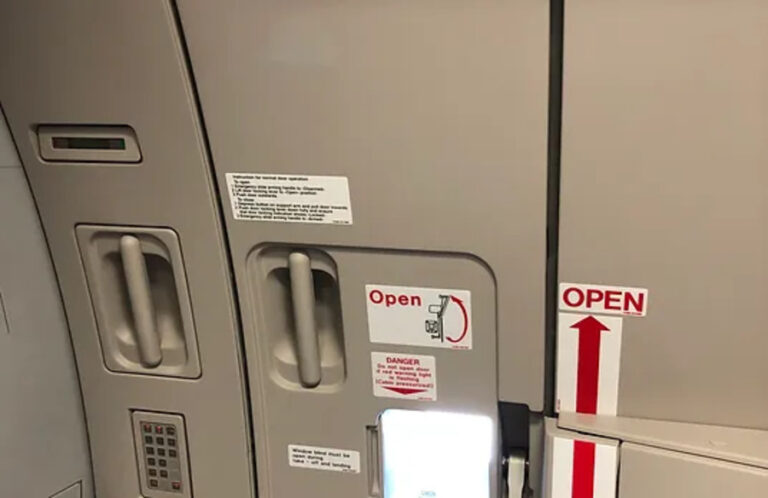

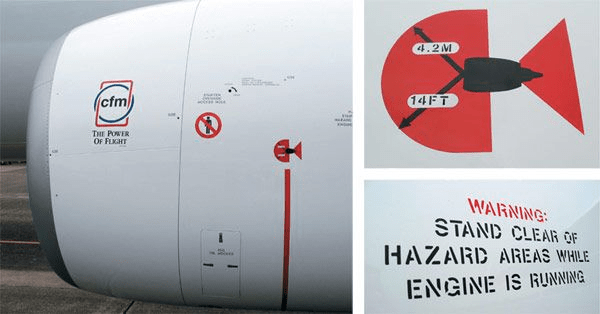

Aircraft Placards & Decals

Aircraft placards and decals play a crucial role in aviation safety and regulatory compliance. These small but significant components are essential for conveying critical information to pilots, crew members, and passengers. From emergency procedures to operational limitations, aircraft placards and decals provide clear guidance and reminders that are vital for safe and efficient flight operations.

One of the primary functions of aircraft placards and decals is to communicate emergency procedures and equipment locations. In the event of an emergency, quick and accurate access to information can be the difference between a successful outcome and a potential disaster. Placards and decals strategically placed throughout the aircraft serve as visual cues, guiding passengers and crew to essential safety features such as emergency exits, life vests, and fire extinguishers.

Furthermore, aircraft placards and decals communicate important operational information to pilots and maintenance personnel. They denote critical data such as weight and balance limits, fuel capacity, engine specifications, and maintenance schedules. By adhering to these guidelines, aviation professionals ensure that the aircraft operates within its designated parameters, minimizing the risk of accidents or mechanical failures.

Regulatory compliance is another significant aspect of aircraft placards and decals. Aviation authorities worldwide impose strict regulations regarding the content, placement, and visibility of these markings. Compliance with these regulations is mandatory for all aircraft operators to maintain airworthiness and ensure the safety of passengers and crew. Consequently, manufacturers and operators must carefully design, produce, and install placards and decals in accordance with regulatory requirements.

Advancements in technology have also influenced the design and production of aircraft placards and decals. Modern techniques such as digital printing, laser cutting, and adhesive technologies have improved the durability, flexibility, and customization capabilities of these markings. Moreover, digital documentation and management systems enable operators to efficiently track and update placards and decals as needed, ensuring compliance with evolving regulations and operational requirements.

In conclusion, aircraft placards and decals are indispensable components of aviation safety and regulatory compliance. By providing clear and concise information to pilots, crew members, and passengers, these markings contribute to the overall safety and efficiency of flight operations. As technology continues to advance, the role of aircraft placards and decals will evolve, but their fundamental importance in aviation safety will remain unchanged.